World’s First Compostable Flexible Packaging

A perfect fit for your product. It works as hard as you do, then disappears—leaving no carbon footprint, only a better choice.

Sustainable products

your every need

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 110 ML | 4.0+/-0.5 | 110 | 76.5 | 76.5 | 58 | 125 | 2000 | 1.17 | Tea | Coffee | Chaas |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 4 Inch | 4.0 +/- 0.5 | 150 | 101 | 101 | 26 | 125 | 2000 | 0.89 | 450X230X450 | Chaat | Sweets | Snacks |

| 120ml | 3.5 +/- 0.5 | 120 | 88 | 88 | 33 | 125 | 2000 | 0.92 | 370X190X295 | Chaat | Sweets | Ice Cream |

| 180ml | 4.0 +/- 0.5 | 180 | 105 | 105 | 35 | 125 | 2000 | 1.06 | 432X221X235 | Garvies | Chutney | Daal |

| 250ml | 6.0 +/- 0.5 | 250 | 130 | 105 | 35 | 125 | 2000 | 1.47 | 430X267X260 | Daal | Sambar | Fruit Chaat |

| 360ml | 9.0+/-1.0 | 360 | 135.9 | 135.9 | 35.6 | 125 | 2000 | 2.10 | 580X290X530 | Chaat | Maggie | Haleem |

| Parameter | Unit | Brown Bag Plain |

|---|---|---|

| Grammage | g/m² | 70 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 2.00 |

| Burst Factor | – | 25 |

| Burst Index | Kpa.m²/g | 2.45 |

| Tear Factor | – | 55 |

| Tear Index | mNm²/g | 5.40 |

| Tensile Strength | Kg/15 mm | 3.5 |

| Breaking Length | Meter | 4000 |

| Cobb 60 | g/m² | 30 |

| Brightness (min) | % | – |

| Parameter | Unit | BBR | |

|---|---|---|---|

| 40 | 65 | ||

| Grammage | g/m² | 40 | 65 |

| Burst Strength | Kg/cm² | 0.96 | 1.62 |

| Burst Factor | – | 24 | 25 |

| Burst Index | Kpa.m²/g | 2.35 | 2.45 |

| Tear Factor | – | 55 | 55 |

| Tear Index | mNm²/g | 5.40 | 5.40 |

| Tensile Strength | Kg/15 mm | 2.5 | 3.5 |

| Breaking Length | Meter | 4000 | 4000 |

| Cobb 60 | g/m² | 30 | 30 |

| Brightness (min) | % | – | – |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| Party Caddy | 167.80 +/-1.0 | NA | 240 | 35 | 160 | NA | 36 | 109 | 570X325X345 | Small Parties | Picnic | Bakery |

| Spoon Caddy | 105.20+/-1.0 | NA | 60 | 60 | 170 | 32 | 60 | 99 | 490X400X345 | Small Parties | Picnic | Bakery |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 350ml Delivery Container | 15.0+/-1.0 | 350 ml | 143.3 | 143.3 | 56.9 | 125 | 1000 | 3.14 | 320X320X370 | Graveys | Pasta | Meal Bowls |

| 500ml Delivery Container | 18.0 +/- 1.0 | 500 | 143.4 | 143.3 | 74.1 | 125 | 1000 | 4.16 | 320X320X370 | Graveys | Pasta | Meal Bowls |

| 350/500ml Delivery Container Lid | 13.0 +/- 1.0 | NA | 149.3 | 149.3 | 12.6 | 125 | 1000 | 2.86 | 350X350X370 | |||

| 750ml Delivery Container | 20.0 +/- 1.0 | 750 | 184.3 | 184.3 | 60.4 | 125 | 750 | 5.2 | 400X400X315 | Graveys | Pasta | Meal Bowls |

| 1000ml Delivery Container | 24.0 +/- 1.0 | 1000 | 184.3 | 184.3 | 74.3 | 125 | 750 | 6.24 | 400X400X450 | Graveys | Pasta | Meal Bowls |

| 750/1000 Delivery Container Lid | 16.0 +/- 1.0 | NA | 190.3 | 190.3 | 12.6 | 125 | 750 | 3.64 | 400X400X400 |

| Parameter | Unit | Deluxe Plain | |

|---|---|---|---|

| Grammage | g/m² | 38 | 80 |

| GSM Variation | % | ± 5 | ± 5 |

| Burst Strength | Kg/cm² | 0.69 | 1.60 |

| Burst Factor | – | 18 | 20 |

| Burst Index | Kpa.m²/g | 1.77 | 1.96 |

| Tear Factor | – | 45 | 50 |

| Tear Index | mNm²/g | 4.42 | 4.91 |

| Tensile Strength | Kg/15 mm | 1.5 | 3.0 |

| Breaking Length | Meter | 3300 | 3300 |

| Cobb 60 | g/m² | 45 | 45 |

| Brightness (min) | % | – | – |

| Parameter | Unit | Deluxe Ribbed (DER) |

|---|---|---|

| Grammage | g/m² | 60 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 1.40 |

| Burst Factor | – | 20 |

| Burst Index | Kpa.m²/g | 1.96 |

| Tear Factor | – | 50 |

| Tear Index | mNm²/g | 4.91 |

| Tensile Strength | Kg/15 mm | 3.0 |

| Breaking Length | Meter | 3300 |

| Cobb 60 | g/m² | 45 |

| Brightness (min) | % | – |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 500ml | 15.0 +/- 1.0 | 500 | 237 | 132 | 40 | 125 | 1000 | 3.14 | 540X495X325 | Salad | Pasta | Noodles |

| 500ml Lid | 15.0 +/- 1.0 | NA | 244.7 | 177.8 | 12.6 | 125 | 500 | 3.14 | 515X370X380 | |||

| 750ml | 19.0 +/- 1.5 | 750 | 287 | 157 | 40 | 125 | 500 | 3.7 | 590X325X330 | Salad | Pasta | Noodles |

| 750ml Lid | 19.0 +/- 1.0 | NA | 295 | 203 | 12.6 | 125 | 500 | 3.7 | 610X395X336 |

| Parameter | Unit | Eco Pouch Base |

|---|---|---|

| Grammage | g/m² | 68 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 1.90 |

| Burst Factor | – | 28 |

| Burst Index | Kpa.m²/g | 2.75 |

| Tear Factor | – | 55 |

| Tear Index | mNm²/g | 5.40 |

| Tensile Strength | Kg/15 mm | 4.0 |

| Breaking Length | Meter | 4000 |

| Cobb 60 | g/m² | 25 |

| Brightness (min) | % | 82 |

| Parameter | Unit | Golden Super Deluxe Ribbed |

|---|---|---|

| Grammage | g/m² | 40 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 0.80 |

| Burst Factor | – | 20 |

| Burst Index | Kpa.m²/g | 1.96 |

| Tear Factor | – | 50 |

| Tear Index | mNm²/g | 4.91 |

| Tensile Strength | Kg/15 mm | 2.0 |

| Breaking Length | Meter | 3300 |

| Cobb 60 | g/m² | 28 |

| Brightness (min) | % | – |

| Parameter | Unit | KBP |

|---|---|---|

| Grammage | g/m² | 40 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 1.12 |

| Burst Factor | – | 28 |

| Burst Index | Kpa.m²/g | 2.75 |

| Tear Factor | – | 50 |

| Tear Index | mNm²/g | 4.91 |

| Tensile Strength | Kg/15 mm | 3.5 |

| Breaking Length | Meter | 5000 |

| Cobb 60 | g/m² | 30 |

| Brightness (min) | % | – |

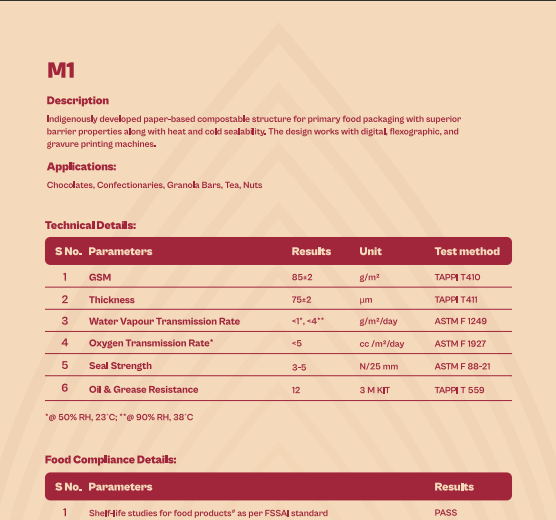

| SNo. | Parameters | Results | Unit | Test Method |

| 1 | GSM | 85±2 | g/m² | TAPPI T410 |

| 2 | Thickness | 75±2 | µm | TAPPI T411 |

| 3 | Water Vapour Transmission Rate | <1*, <4* | g/m²/day | ASTM F 1249 |

| 4 | Oxygen Transmission Rate* | <5 | cc /m²/day | ASTM F 1927 |

| 5 | Seal Strength | 3-5 | N/25 mm | ASTM F 88-21 |

| 6 | Oil & Grease Resistance | 12 | 3 M KIT | TAPPI T 559 |

@ 50% RH, 23’C; * @ 90% RH, 38’°C

Food Compliance Details

| SNo. | Parameters | Results |

| 1 | Shelf-life studies for food products* as per FSSAI standard | PASS |

| 2 | Overall Migration Test performance as per IS 9845:1998(RA:2015) | PASS |

| 3 | Specific Migration of Heavy Metals | PASS |

| 4 | Specific Migration of Bis(2-ethylhexyl) phthalate [DEHP] | PASS |

#12 months shelf life for chocolates has passed at ambient conditions.

Compostability Certificates

| 1 | Compostable as per ISO 17088:2021 | CIPET |

| SNo. | Parameters | Results | Unit | Test Method |

| 1 | GSM | 56±2 | g/m² | TAPPI T410 |

| 2 | Thickness | 54±3 | µm | TAPPI T411 |

| 3 | Water Vapour Transmission Rate * | <2 | g/m²/day | ASTM F 1249 |

| 4 | Oxygen Transmission Rate* | <8 | cc /m²/day | ASTM F 1927 |

| 5 | Seal Strength | 2-3 | N/25 mm | ASTM F 88-21 |

| 6 | Oil & Grease Resistance | 12 | 3 M KIT | TAPPI T 559 |

*50% RH, 23°C

Food Compliance Details

| SNo. | Parameters | Results |

| 1 | Repulpability as per CPRI testing condition | PASS |

| 2 | Shelf-life studies for food products as per FSSAl standard | Under lab study |

| 3 | Overall Migration Test performance as per IS 9845:1998(RA:2015) | PASS |

| 4 | Specific Migration of Heavy Metals | PASS |

| Specific Migration of Bis(2-ethylhexyl) phthalate [DEHP] | PASS |

Compostability Certificates

| 1 | Compostable as per ISO 17088:2021 | Under CIPET Study |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 3 CP Chombo | 18.00 +/- 1.5 | 545 | 220 | 220 | 25 | 125 | 500 | 3.61 | 510X400X280 | Idli Sambhar | Vada | Pao Bhaji |

| 4 CP | 32.0 +/- 2.5 | 1200 | 304 | 247 | 32 | 125 | 500 | 5.85 | 621X252X528 | Dosa | Chola Bhatura | Thaali |

| 5 CP | 32.0 +/- 2.5 | 1100 | 304 | 247 | 32 | 125 | 500 | 6.65 | 621X252X528 | Dosa | Chola Bhatura | Thaali |

| 8 CP | 38.0 +/- 2.5 | NA | 312 | 255 | 35 | 125 | 500 | 7.88 | 560X345X560 | Mix Thali | ||

| 4CP Chausar | 22.0 +/- 1.0 | NA | 265 | 265 | 30.6 | 125 | 500 | 4.66 | 550X280X370 | Chalo bhatura | Chola Kulcha | Paratha |

| Parameter | Unit | Middle East Bag Ribbed | |

|---|---|---|---|

| Grammage | g/m² | 50 | |

| GSM Variation | % | ±5 | |

| Burst Strength | Kg/cm² | 1.25 | |

| Burst Factor | – | 25 | |

| Burst Index | Kpa.m²/g | 2.45 | |

| Tear Factor | – | 55 | |

| Tear Index | mNm²/g | 5.40 | |

| Tensile Strength | Kg/15 mm | 3.2 | |

| Breaking Length | Meter | 4000 | |

| Cobb 60 | g/m² | 30 | |

| Brightness (min) | % | – | |

| Parameter | Unit | NSP | |

| Grammage | g/m² | 35 | 50 |

| GSM Variation | % | ±5 | ±5 |

| Burst Strength | Kg/cm² | 0.7 | 1.1 |

| Burst Factor | – | 20 | 22 |

| Burst Index | Kpa.m²/g | 1.96 | 2.16 |

| Tear Factor | – | 45 | 55 |

| Tear Index | mNm²/g | 4.41 | 5.4 |

| Tensile Strength | Kg/15 mm | 1.8 | 2.5 |

| Breaking Length | Meter | 3800 | 3800 |

| Cobb 60 | g/m² | 28 | 28 |

| Brightness (min) | % | 82 | 82 |

| SNo. | Parameters | Results | Unit | Test Method |

| 1 | GSM | 62±2 | g/m² | TAPPI T410 |

| 2 | Thickness | 70±2 | µm | TAPPI T411 |

| 3 | Water Vapour Transmission Rate* | <5 | g/m²/day | ASTM F 1249 |

| 4 | Seal Strength | 2±3 | N/25 mm | ASTM F 88-21 |

50% RH, 23°C

Food Compliance Details

| SNo. | Parameters | Results |

| 1 | Repulpability as per CPPRI testing condition | PASS |

| 2 | Shelf-life studies for food products as per FSSAl standard | Under lab study |

| 3 | Overall Migration Test performance as per IS 9845:1998(RA:2015) | Under lab study |

| 4 | Specific Migration of Heavy Metals | Under lab study |

| 5 | Specific Migration of Bis(2-ethylhexyl) phthalate [DEHP] | Under lab study |

Compostability Certificates

| 1 | Compostable as per ISO 17088:2021 | Under CIPET Study |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 6 inch | 6.5 +/- 0.5 | NA | 152.5 | 152.5 | 20 | 125 | 2000 | 1.33 | 321X321X396 | Fruit chaat | Chaat | Kabab |

| 7 Inch | 7.5 +/- 1.0 | NA | 156 | 156 | 20 | 125 | 2000 | 1.58 | 380X380X380 | Chaat | Rajkachori | Snacks |

| 9 Inch | 15.0 +/- 1.0 | NA | 229 | 229 | 20 | 125 | 500 | 2.99 | 475X240X435 | Kulcha | Pizza | Waffles |

| 10 Inch | 18.0 +/- 1.5 | NA | 255 | 255 | 20 | 125 | 500 | 3.42 | 527X267X375 | Chole bhature | Pizza | Paratha |

| 11 Inch | 27.0 +/- 2.0 | 750 | 253 | 253 | 20 | 125 | 500 | 4.75 | 257X267X510 | Chole bhature | Small Thali | Paratha |

| 12 Inch | 27 +/- 2.0 | NA | 305 | 305 | 20 | 125 | 500 | 5 | 640X320X350 | Big Meal Thali | Pizza | Sapad |

| Parameter | Unit | PBB |

| Grammage | g/m² | 40 |

| GSM Variation | % | ±5 |

| Burst Strength | Kg/cm² | 0.88 |

| Burst Factor | – | 22 |

| Burst Index | Kpa.m²/g | 2.16 |

| Tear Factor | – | 55 |

| Tear Index | mNm²/g | 5.4 |

| Tensile Strength | Kg/15 mm | 3 |

| Breaking Length | Meter | 4000 |

| Cobb 60 | g/m² | 28 |

| Brightness (min) | % | 82 |

| Product Name | Weight in Gms | Volume | Length | Width | Depth | Inner Pack | Pack Size | Price/Pc | CTN Size | Use Case 1 | Use Case 2 | Use Case 3 |

| 3 CP Snack Tray | 16.0+/-1.0 | NA | 210.6 | 165 | 35.6 | 125 | 1000 | 3.23 | 435X345X530 | Nachos | Momo’s | Fries |

| Parameter | Unit | Super Deluxe Plain |

|---|---|---|

| Grammage | g/m² | 50 |

| GSM Variation | % | ± 5 |

| Burst Strength | Kg/cm² | 1.10 |

| Burst Factor | – | 22 |

| Burst Index | Kpa.m²/g | 2.15 |

| Tear Factor | – | 60 |

| Tear Index | mNm²/g | 5.88 |

| Tensile Strength | Kg/15 mm | 2.5 |

| Breaking Length | Meter | 3500 |

| Cobb 60 | g/m² | 35 |

| Brightness (min) | % | – |

| Parameter | Unit | Super Eco Poster | |

|---|---|---|---|

| 38 | 50 | ||

| GSM Variation | % | ±5 | ±5 |

| Burst Strength | Kg/cm² | 0.53 | 0.70 |

| Burst Factor | – | 14 | 14 |

| Burst Index | Kpa.m²/g | 1.37 | 1.37 |

| Tear Factor | – | 40 | 45 |

| Tear Index | mNm²/g | 3.92 | 4.4 |

| Tensile Strength | Kg/15 mm | – | – |

| Breaking Length | Meter | 3000 | 3000 |

| Cobb 60 | g/m² | 35 | 35 |

| Brightness (min) | % | 82 | 82 |

| Parameter | Unit | Super Wrapping Poster | |

|---|---|---|---|

| 30 | 40 | ||

| GSM Variation | % | ±5 | ±5 |

| Burst Strength | Kg/cm² | 0.48 | 0.67 |

| Burst Factor | – | 16 | 16 |

| Burst Index | Kpa.m²/g | 1.57 | 1.57 |

| Tear Factor | – | 45 | 45 |

| Tear Index | mNm²/g | 4.41 | 4.41 |

| Tensile Strength | Kg/15 mm | – | – |

| Breaking Length | Meter | 3500 | 3500 |

| Cobb 60 | g/m² | 30 | 30 |

| Brightness (min) | % | 82 | 82 |

Our eco-friendly product pathway

You get exactly what your product needs. When the customer finishes— the packaging just vanishes into the earth. Perfect for you…and even better for the planet.

Understanding your needs

Custom packaging starts with you

From idea to prototype

Designed, tested, and refined

Perfect with you

Your feedback shapes the final product

Ready for the market

Packaging that serves, then disappears

We work closely to understand the product needs and design the perfect flexi packaging – just for you!

Every prototype goes through rigorous quality checks, including temperature and freshness tests, to ensure it meets your expectations

We tweak and refine based on your trials, ensuring the packaging is just right—because no one knows your product better than you!

Once your flexi packaging hits the market, it does its job and returns to the earth—biodegrading naturally without a trace

We work closely to understand the product needs and design the perfect flexi packaging – just for you!

Every prototype goes through rigorous quality checks, including temperature and freshness tests, to ensure it meets your expectations

We tweak and refine based on your trials, ensuring the packaging is just right—because no one knows your product better than you!

Once your flexi packaging hits the market, it does its job and returns to the earth—biodegrading naturally without a trace

Together, we take small steps

towards making a bigger

impact

Every small step we take together builds momentum toward creating a lasting, positive impact on our planet. By uniting our efforts, we’re making significant strides in shaping a more sustainable future.

95% of chemicals are recovered

That’s all it takes for our products to return to nature

That’s what powers our operations, naturally

Back into the stream, right where it belongs

Awards and Recognition

Resources for a greener Future

Join us in

making a difference

If you want your business to make a lasting impact on the planet, we’d love to connect with you. With businesses doing better today, the future looks better.